High Racer Recumbent

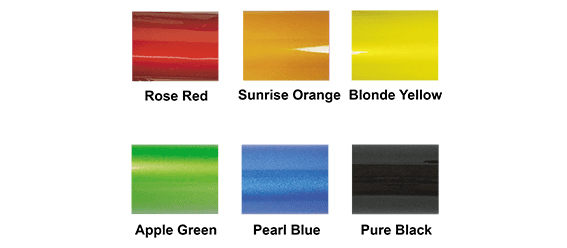

Choose Your Color

Specifications

20 Speed

22 Speed

Bike Sizing & Fit Guide

20 Speed

| Item | Description |

|---|---|

| Frame | Alloy 7005 |

| Front fork | Full carbon fiber |

| Seat | FRP w/headrest |

| Handle bar | mini bar with alloy tiller |

| Tiller | internal cable route tiller with stem |

| Shifter | Microshift Bar End Shifter M10 |

| Lever | Tektro CL-530 |

| Front derailleur | Microshift FD-M612B |

| Rear derailleur | Microshift RD-M61L |

| Crankset | FSA 46/30T 170L |

| Cassette | Microshift CS-H100 11-32T |

| Wheelset | DT SWISS R24 |

| Tires | Good Year 700 x 25c |

| Brakes | REVER MCX02 disc brake |

| MSRP | US$2,125 |

22 Speed

| Item | Description |

|---|---|

| Frame | Alloy 7005 |

| Front fork | Full carbon fiber |

| Seat | FRP w/headrest |

| Handle bar | mini bar with alloy tiller |

| Tiller | internal cable route tiller with stem |

| Shifter | Microshift Bar End Shifter M11 |

| Lever | Tektro CL-530 |

| Front derailleur | Microshift FD-M622B |

| Rear derailleur | Microshift RD-M665L |

| Crankset | FSA 46/30T 170L |

| Cassette | Microshift CS-H100 11-32T |

| Wheelset | DT SWISS R24 |

| Tires | Good Year 700 x 25c |

| Brakes | REVER MCX02 disc brake |

| MSRP | US$2,235 |

Bike Sizing & Fit Guide

| Wheel Size | Bottom Bracket Height | Seat Height | Seat angle-from Horizontal | Top of seat | Top of Headrest |

|---|---|---|---|---|---|

| 700c | 76cm | 57.5cm | 23° | 89cm | 105cm |

| Wheel base | Average weight/kg | Rider’s weight limited | X-seam/inch | Warranty | |

| 113.5cm | 13.8kgs | 110kgs | above 40.5″ | 5 Years |

*The components may change due to the availability.

Description

Performer’s Recumbent Bike Range starts with the Lacka. This recumbent is a basic, solid, dependable workhorse that will get you where you want to go—and more than a good way beyond that. The 11-36t cassette gives you the ability to comfortably climb just about any gradient you are likely to come across. That’s in combination with the 30t chainring. The 11t in combination with the 52t chainring will get you humming along and passing the wedgies at a rate that’ll have them seriously reconsidering the whole upright bike thing. Let the Bent revolution continue! The seat is a generously proportioned FRP shell base covered in supportive yet supple foam.

A great benefit of the Lacka is the the front forks. These forks will allow you to fit either a 26″ or a 700c wheel. This is one difference that marks the Lacka off from the Goal 26x[LINK] which will only take a 26″ wheel. Of course, one advantage of the Goal is that you get suspension.

The 7005 alloy used in the frame is standard aircraft aluminum. Cheaper bike frames are made out of 6061. With 7005 you are getting a lighter frame. All higher-end aluminum frames will use 7005. It’s not a case of whether 7005 is better than 6061. 6061 is used for stems, handlebars, seat tubes and so forth. It’s just that 7005 is better suited for creating a higher quality frame. It comes down to the heat treatment that is essential to creating a safe, light frame.

Basically, Aluminum is a soft alloy. Steel (eg. Chrome-Moly) is stronger, but heavier of course. Heat treatments are essential for getting a frame “hard” enough so it can perform its job. The first aspect to this is the welding. When aluminum frame tubes are welded together, this makes the area around the weld a lot harder than the rest of the frame. A “T4” heat treatment is required to return the frame to it’s uniform state prior to the T4 treatment. T6 heat treatment is the next stage. This is necessary to harden—and thus strengthen—the frame uniformly. For a 7005 frame we proceed with two stages with the frames being air cooled. 6061, in contrast is subject to the one heat treatment and liquid cooled. That brings on rapid cooling and is not appropriate for 7005.